Most asphalt businesses offer milling services. However, a majority of consumers do not necessarily know or understand what milling is. Pavement milling is an important part of the asphalt paving process. Read all about pavement milling and how it works.

What Is Milling?

Pavement milling is the process that removes pavement from where it has been laid. The process is also known as cold planing. Asphalt professionals use milling for a couple of situations. The process is dynamic because it can remove just the surface of the asphalt or all of the asphalt in its entirety. The process of removing all of the asphalt is called a full depth removal.

How The Process Works

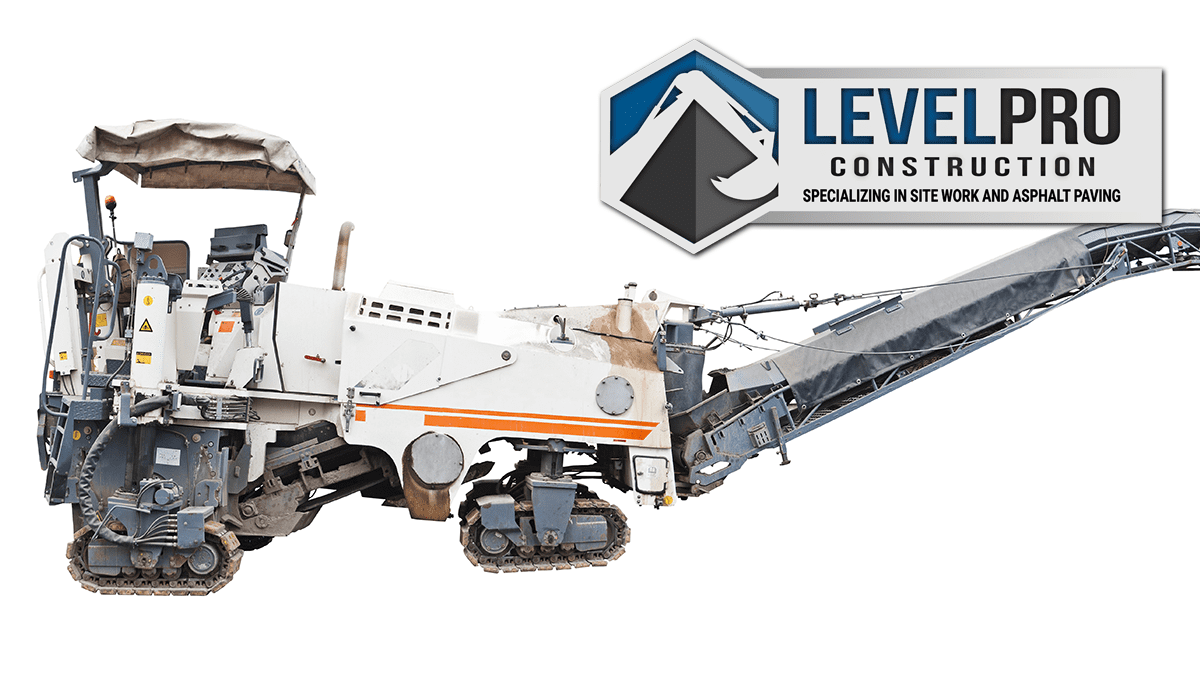

Asphalt experts use a machine called a milling machine or cold planer during the process. This machine is fairly large and looks like a bulldozer with a conveyor belt instead of a digging instrument. It is used in conjunction with a dump truck, which gathers the broken-up asphalt.

The machine uses a large rotating drum to collect the asphalt before spitting it back out. The rotating drum is full of large blades made of carbide. Carbide is an industrial material that is comparable to steel in its durability. The huge blades grind the asphalt into manageable pieces and collect the pieces in the center of the drum.

From there, the pieces are moved out of the center of the drum to the conveyor belt. The conveyor belt then pulls the asphalt out of the milling machine and to the dump truck.

Outside of the drum there is usually water or some other coolant that serves a few purposes. First and foremost, it prevents the constantly moving and grinding drum from overheating. Additionally, this barrier prevents too must dust and debris from escaping into the air.

Situations To Use Pavement Milling

Smooth The Road

There is a process called micro milling which is excellent for smoothing and evening out bumpy roads. The micro version of the process uses a drum which has many more blades in it. However, the blades are shorter than typical cold planer machine. Due to the shorter length of the blades, micro milling really only removes the surface of the road. This surface-level removal is perfect for road smoothing and evening though. Shaving off the top of the road makes the smooth asphalt underneath much more pleasant to drive on.

Rumble Strips

Rumble strips are used on major roads to help prevent accidents. In areas without streetlights, rumble strips serve as a warning on the outside of the road to drivers veering off course. Additionally, rumble strips help to wake sleepy divers who drift off behind the wheel. Micro milling is also used to create rumble strips. This method of creating rumble strips is highly efficient. This is because the cold planer machines make rumble strips out of pre-existing asphalt.

Recycling

If a road needs to be repaved, milling helps asphalt professionals do so in an environmentally friendly way. The broken up old asphalt is upcycled into aggregate for the new road.